22.06.2020 Kamen, Germany

Theme-specific event: DynaWeld day – resource-efficient manufacturing

Location: DynaWeld GmbH & Co. KG, Herbert-Wehner-Straße 2 , 59174 Kamen, room 1-3

DynaWeld day – resource-efficient manufacturing

DynaWeld specializes in thermally influenced manufacturing processes and advises designers and manufacturing companies on the construction and design of their production.

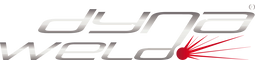

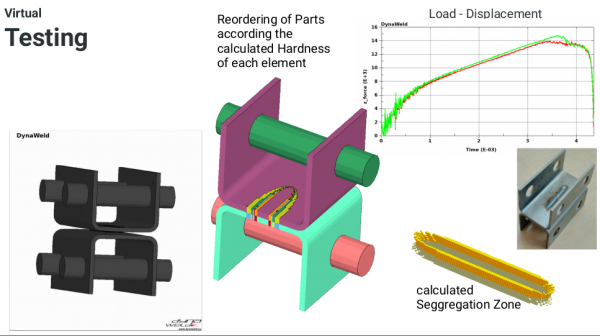

DynaWeld uses meaningful simulations, based on self-developed or further developed methods. DynaWeld is able to analyse production processes independently of existing production, points out vulnerabilities and works out optimized solutions with the customer. With help of simulation, this is already possible in the early design phase.

At the DynaWeld Day we want to give you an overview of the various possibilities to save resources and costs through targeted planning in process and manufacturing design. Starting with energy saving through furnace optimization up to the avoidance of wrong production or unnecessary test loops.

The basis is a precise simulation of the manufacturing processes developed by DynaWeld:

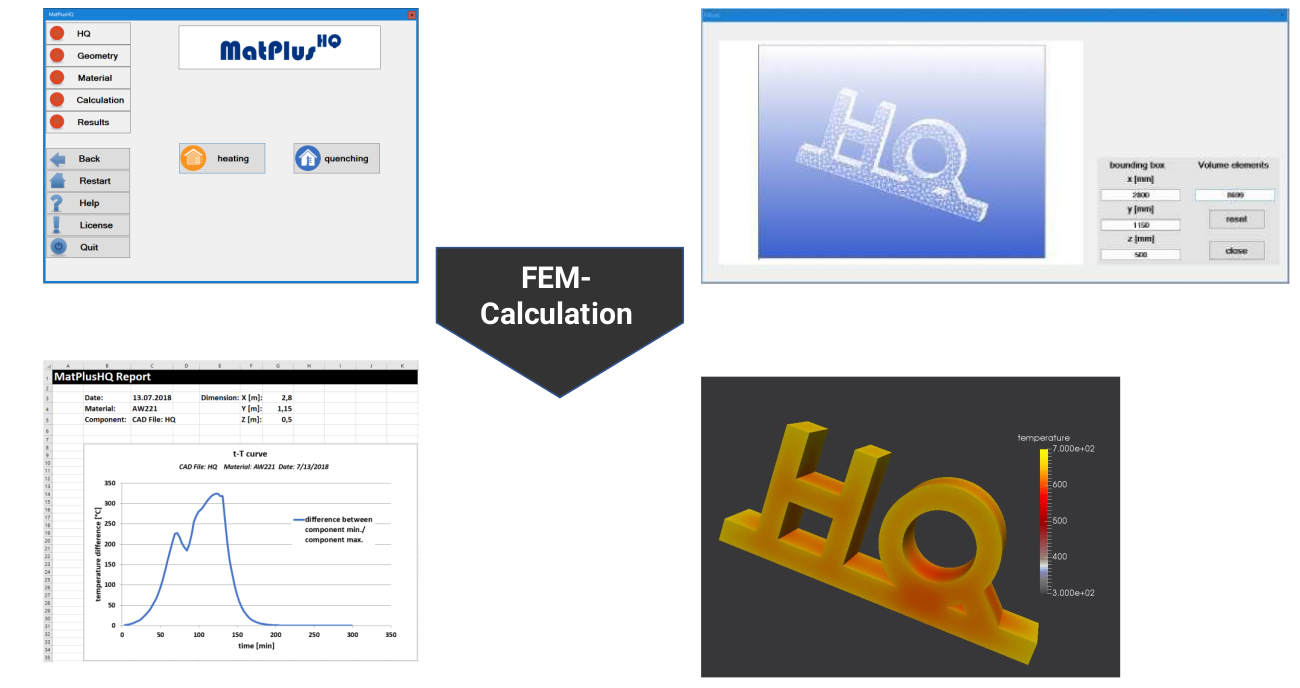

• Welding and welding assembly

• Heat Treatment

• Hot forming

Simulatively determined weld load capacity with DynaWeld

Thermally influenced manufacturing processes change the material intentionally (heat treatment) as well as unintentionally (welding). Simulations allow DynaWeld to make statements about the material and component conditions and to support you in designing processes economically so that the desired conditions are achieved:

• hardness

• microstructure

• residual stresses

Program:

| 10:00 | Anmeldung |

| 11:00 |

Begrüßung und Vorstellung der DynaWeld |

| 11:15 |

Einsparpotentiale in der Wärmebehandlung |

| 11:45 |

Welche Vorhersagegenauigkeit liefert die Schweißverzugsberechnung |

| 12:15 |

Simulationsbasierte Auslegung des Schweißzusammenbaus: |

| 13:00 |

Mittagsimbiß |

| 14:00 |

Prozeßauslegung für die Warmumformung, wie garantiert |

| 14:20 |

Induktive Erwärmung: Potentiale der gezielter |

| 14:40 |

Wärmeführung beim Schweißen und in der additiven |

| 15:00 |

Simulative Festigkeitsbewertgung von Schweißverbindungen |

| 15:20 |

Diskussion |

| 15:45 |

Verabschiedung |

target group

- Manager

- Welding supervisors

- Engineers and designers

- technical and commercial management

Participation fee including meals:

Participation is free of charge

Registration deadline: June 12, 2020

Max. number of participants: 40 people

The DynaWeld Day takes place from 10 people.

Registration:

DynaWeld GmbH & Co. KG

Herbert-Wehner-Strasse 2

59174 Kamen

Phone: +49 (0) 2307 5000 505

e-mail: info@dynaweld.de

or via the following registration form: