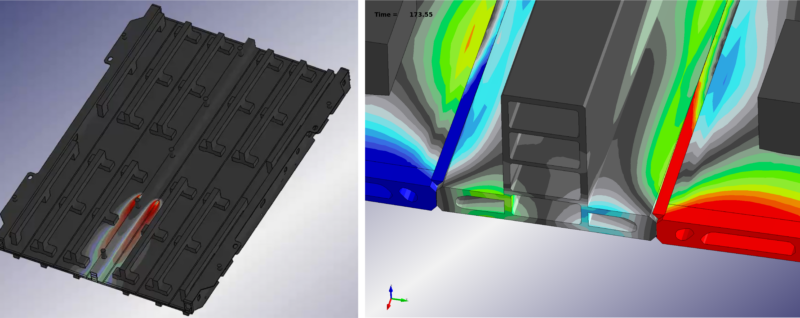

Thermal expansions already lead to deformation of the components during welding. This can lead to components moving apart at the joining zone. The formation of this gap endangers process stability and leads to significant shape deviations.

This gap formation is to be limited or prevented with a clamp device. Alternatively, tack welds are used to fix the components. With the Dynaweld welding simulation and the Free Motion Filler method developed by DynaWeld it is possible to analyze this gap formation simulatively. A selected clamping concept can thus be numerically approved in advance. It is also possible to check the draft of a tack weld concept. This means that any high consequential costs of subsequent correction interventions in production can be avoided in advance. The more advanced production planning is, the higher these costs tend to be. In the worst possible case, that would be the production shutdown. This applies not only to undesired gaps, but also to welding distortions in general.

You can find an example of this in our video DynaWeld Gap-Analysis: