Archive

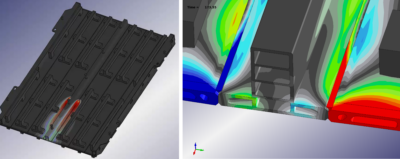

Detect gap formation during welding with DynaWeld welding simulation

Thermal expansions already lead to deformation of the components during welding. This can lead to components moving apart at the joining zone. The formation of this gap endangers process stability and leads to significant shape deviations. This gap formation is to be limited or prevented with a clamp device. Alternatively, tack welds are used to fix the components. With [...]

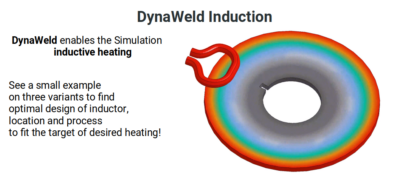

Induction hardening with DynaWeld

Induction is an efficient method for targeted heating. Components can be heated both completely and partially. Induction heating can be used for welding, straightening, preheating or for heat treatment. We have developed a modeling method to image inductive heating to a 3D model. We use the boundary element method, which means we can do without meshing the air. That [...]

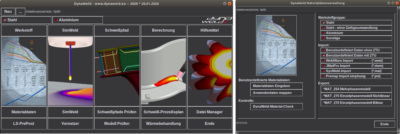

New DynaWeld release available

With the new version of DynaWeld we have prettied up the appearance of the surface. In addition, the user can now choose the colors of the GUI according to his own wishes. In addition to English and German, DynaWeld is now also available in Spanish. At the customer´s request, we can now enter any language. Other functionalities: Simplified [...]

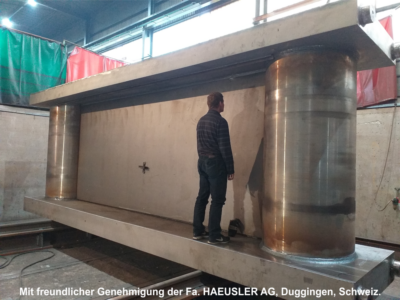

DynaWeld for heavy machinery construction – heat management during welding

Heavy machinery construction places special demands on the design of welded joints. Solid components with sheet thicknesses between 100 mm and 500 mm absorb the welding heat much faster than thin-walled components. The result is high cooling rates with common welding processes such as gas-shielded metal welding or submerged arc welding. Steels that can be welded in the thin [...]

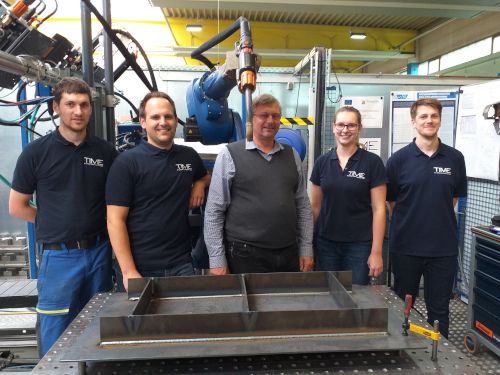

Validation tests for the welding simulation

DynaWeld at the Technology Institute for Metal & Engineering GmbH (TIME) The prediction accuracy of numerical simulations can only be convincing if the models used are suitable for the physical processes and the modeling is realistic. A check can be done on the basis of welding tests. So far, one can find in the literature for verification purposes [...]

DynaWeld at INSIGHT @ Volkswagen Wreśnia 2019

INSIGHT @ Volkswagen Wreśnia 2019 was hosted by the Automotive Circle and took place in Poznan. Highlight: Visit to the new VW plant for the Crafter in Wrenia. In addition to many interesting lectures on body construction with a focus on commercial vehicles, DynaWeld is contributing to digitalization in production planning: Distortion managemnt in the design of the [...]

Simulation Forum Welding and Heat Treatment 2019

Meanwhile, the numerical simulation in the fields of heat treatment and welding is ready for industrial application and offers a future-oriented and innovative working area for engineers in research and practice. Intensive research has been carried out in these areas over the last few years to numerically depict the behavior of materials and components during machining The increasing interest [...]

DynaWeld at the Day of Welding Practice in Rostock

DynaWeld presented its software solutions again this year at the Day of Welding Practice in Rostock. There was also the 25th anniversary of the organizer, the SLV Mecklenburg-Vorpommern. Congratulations on this!

DynaWeld meets Goldak Technologies

DynaWeld spent a week with John Goldak and his team in Ottawa, Ontario, Canada. In addition to intensive expert talks, discussions were held on how welding simulation and heat treatment simulation can be used even more efficiently in the future and how small and medium-sized enterprises can also benefit from it. VrSuite offers a variety of functionalities developed by [...]

Automotive Circle – Joining in Car Body Engineering 2019

In Bad Nauheim (Germany) this year´s conference, organized by the Working Group Automotive Circle, tooke place from 9 to 11 April 2019. In front of an international audience, DynaWeld talked about numerical distortion compensation solutions in BIW constructions. The presented method was developed together with Niels Koch from Opel Automobile GmbH: Digital distortion compensation solution for BIW assemblies by [...]

Studiennamiddag 3 AUTOLAS: Lasmallen, vervorming en lasparameter

Vim Verlinde from Institut Belge de la Soudure (IBS) / Belgisch Instituut voor Lastechniek (BIL) invited DynaWeld to participate in a workshop on welding distortion and welding process parameters with two lectures. One lecture deals with the prediction of weld geometry by calculation: Can we predict weld geometry by simulation?. The second lecture explains how the welding simulation helps [...]